They are particularly effective when used with materials like ceramic tiles or floating floors, providing both sound insulation and comfort underfoot. Installing acoustic underlays beneath carpets in office spaces helps mitigate foot traffic noise and other disturbances, improving room dynamics. Buildtec Acoustics offers underlays made from environmentally friendly materials, such as cork, recycled crumb rubber, and natural wool.

The compatibility with different floor finishes makes acoustic underlays an essential component of modern flooring design, creating a space that is both visually appealing and acoustically comfortable. In rooms with underfloor heating, selecting an underlay with low thermal resistance ensures that heat transfers efficiently without being obstructed by the soundproofing material. Looking to dampen noise in your office then use acoustic underlay under your floor.

These options support environmentalism by reducing reliance on virgin materials and lowering overall pollution. This allows consumers to achieve their preferred aesthetics without sacrificing soundproofing performance.

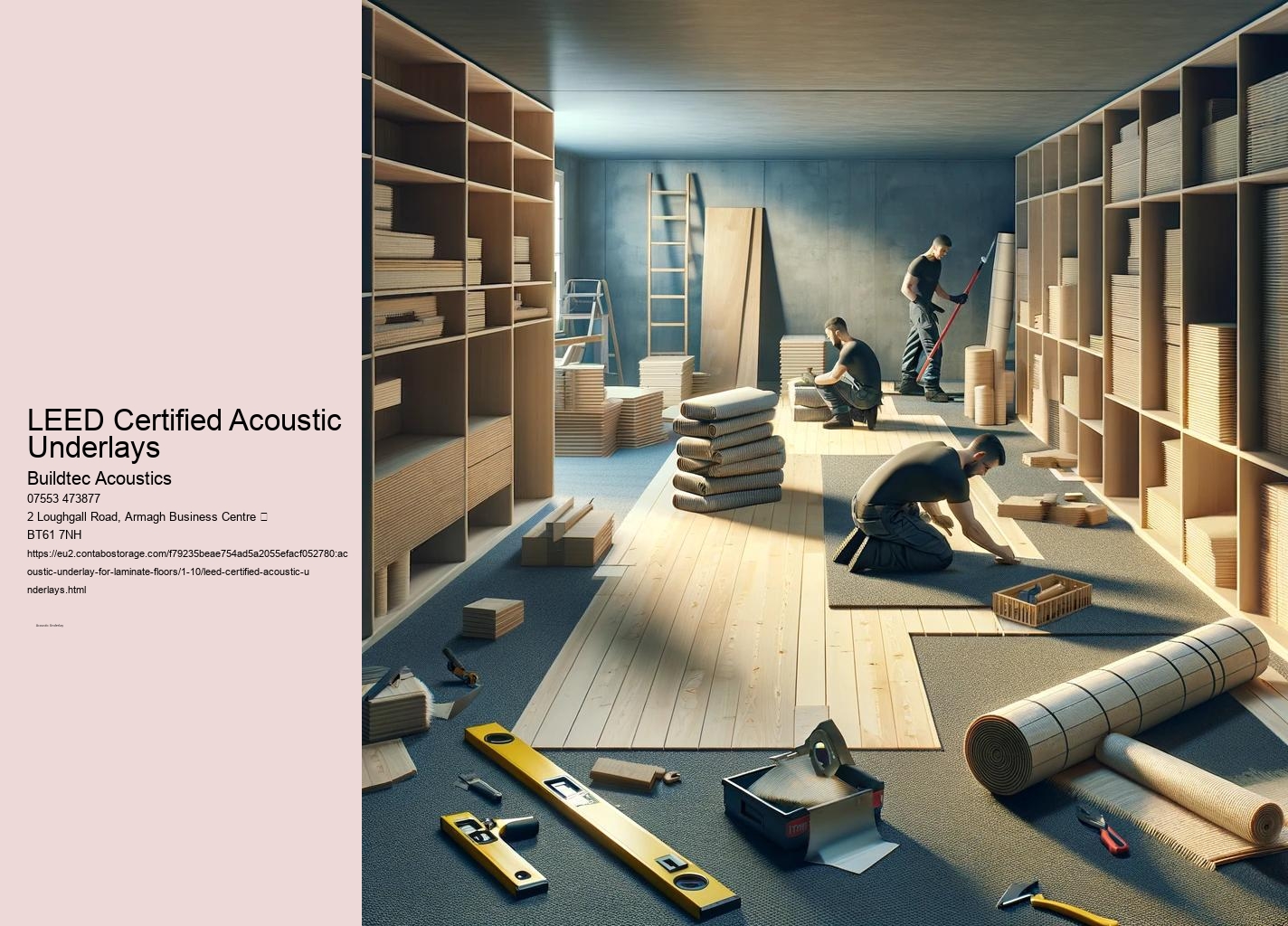

Acoustic underlays are valuable for renovation projects as well. Most underlays come in sheet or roll form and can be cut to size with simple tools like a utility knife.

Acoustic underlays are versatile and suitable for use in various settings, from residential homes to commercial spaces like offices or retail environments. Acoustic underlays work by absorbing and dissipating sound energy, which reduces noise transmission through floors. Whether the flooring type is laminate, ceramic, or hardwood, Buildtec Acoustics offers underlays specifically designed to match the selected material.

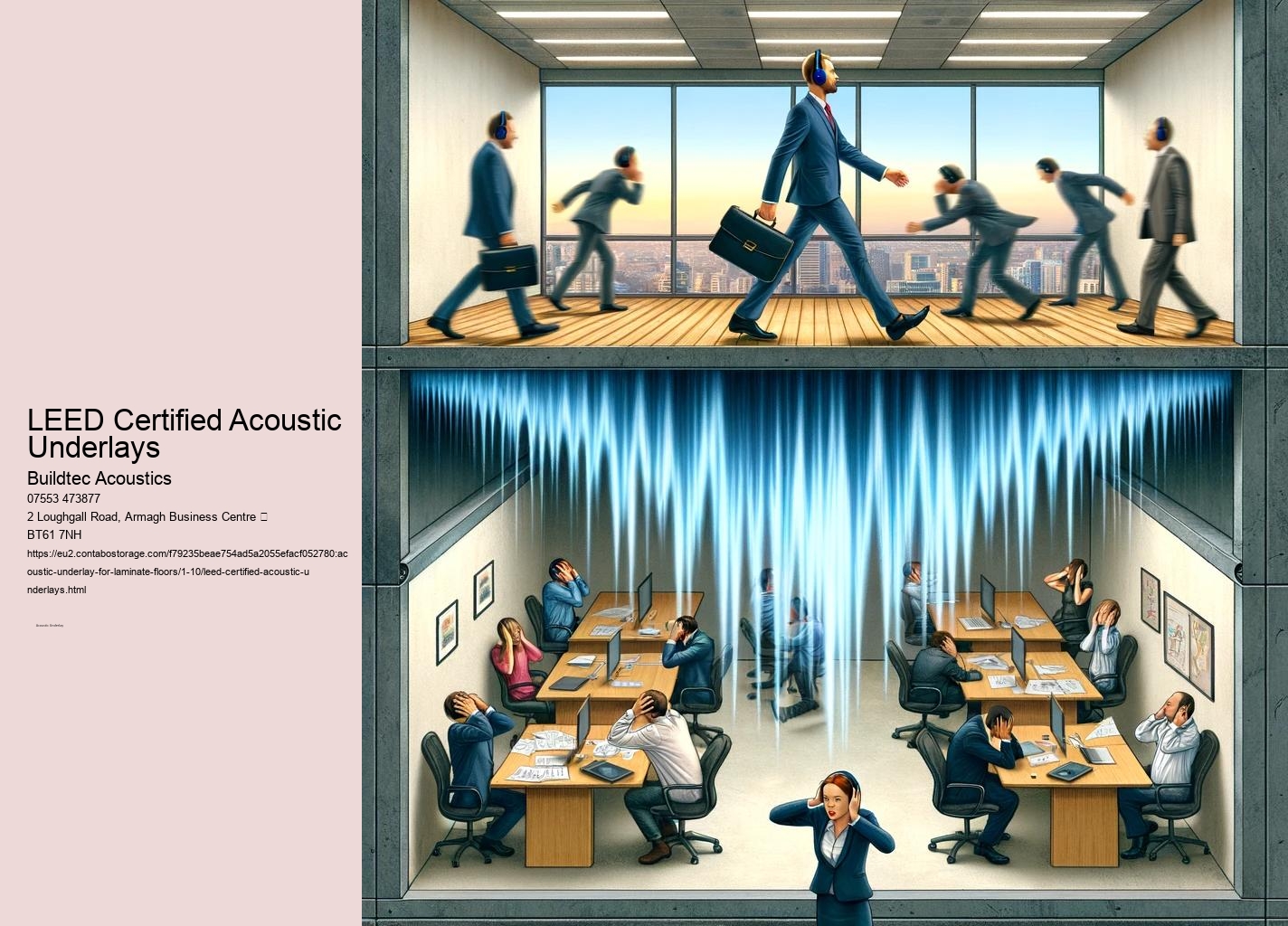

Underlays help isolate vibrations, preventing them from being transmitted through the building structure and reducing their impact on adjacent rooms or units.

Understanding which flooring types are compatible with acoustic underlay.

Posted by Francis Mckenna on

How acoustic underlays contribute to noise reduction in multi-story structures.

Posted by Francis Mckenna on

Exploring the sustainable aspects of acoustic underlays.

Posted by Francis Mckenna on

Buildtec Acoustics offers a wide range of acoustic underlays designed to handle both airborne and impact noise, making them suitable for various flooring applications, including wood flooring, ceramic tiles, and laminate flooring. Acoustic underlays are also effective for vibration isolation, particularly in areas with significant sources of vibration, such as near heating equipment or heavy appliances. Impact noise, like footsteps on laminate flooring or vibrations from a washing machine, can be minimized using dense materials like natural rubber or foam.

Buildtec Acoustics offers a variety of acoustic underlays to meet different needs, including those designed for underfloor heating systems. During renovations, installing acoustic underlays can significantly improve the acoustic properties of existing floors, whether in residential or commercial settings. Acoustic underlays are versatile and can be used in a variety of settings, from residential homes to commercial spaces such as offices or retail environments.

They are installed beneath the visible flooring material, ensuring that the desired flooring-whether it is elegant hardwood, practical laminate, or cozy carpet-remains unaltered. Additionally, these materials are low in volatile organic compound (VOC) emissions, which contributes to a healthier indoor environment.

In conclusion, acoustic underlays from Buildtec Acoustics provide an effective solution for soundproofing floors, enhancing room acoustics, and improving overall comfort. The materials used in acoustic underlays, such as foam, cork, and natural rubber, are highly effective in reducing vibrations and controlling noise.

Impact noise, such as footsteps on laminate flooring or vibrations from appliances, can be minimized using dense materials like natural rubber or foam. This process involves the transformation of sound energy into heat, which then dissipates harmlessly.

This allows consumers to achieve their preferred aesthetics without sacrificing soundproofing performance. Acoustic underlays made from polyvinyl chloride (PVC) or cork are ideal choices, as they balance both thermal insulation and soundproofing requirements. Impact noise occurs from activities such as walking, moving furniture, or using appliances like washing machines, while airborne noise includes sounds like conversations, music, and television.

Adhesive or double-sided tape can be used to secure the underlay in place, ensuring tight seams between pieces to prevent gaps that could affect performance. energy Reducing sound transmission class (STC) and impact insulation class (IIC) ratings in a building helps create a more comfortable space, particularly in multi-story buildings where floors are interconnected through walls and joists, making noise control important.

Airborne noise, such as music or conversations, can be reduced by selecting underlays with higher sound transmission class ratings. They are particularly effective when used with materials like ceramic tiles or floating floors, providing both sound insulation and comfort underfoot.

With a range of materials, including cork, foam, natural rubber, and recycled fibers, Buildtec Acoustics ensures that there is an environmentally friendly and efficient product for every need. With a range of materials, including cork, foam, natural rubber, and recycled fibers, Buildtec Acoustics ensures that there is an environmentally friendly and efficient product for every need.

Airborne noise, such as music or conversations, can be reduced by choosing underlays with higher sound transmission class ratings. thermal conductivity Environmental considerations are an important part of the design of acoustic underlays. When discussing soundproofing solutions, acoustic underlays are a reliable choice for reducing noise pollution, enhancing room acoustics, and creating a quieter and more comfortable environment.

Acoustic underlay is an essential component in managing noise control in residential and commercial spaces. Acoustic underlays are also compatible with a range of flooring materials, including tiles, carpet, and wood.

They are designed to be installed beneath the visible flooring material, meaning that the desired flooring-whether it is elegant hardwood, practical laminate, or cozy carpet-is maintained without alteration. The compatibility with different floor finishes makes acoustic underlays an essential component of modern flooring design, creating a space that is both visually appealing and acoustically comfortable.

In rooms with underfloor heating, selecting an underlay with low thermal resistance allows heat to transfer efficiently without being obstructed by the soundproofing material. Most underlays come in sheets or rolls and can be cut to size with simple tools like a utility knife.

Airborne noise, on the other hand, includes sounds such as conversations, music, and television. These materials also provide thermal insulation, enhancing the thermal resistance of the room while effectively managing noise levels. This process involves transforming sound energy into heat, which then dissipates without causing disturbances.

Some underlays are certified by Leadership in Energy and Environmental Design (LEED) standards, supporting sustainable building practices. Adhesive or double-sided tape can be used to secure the underlay in place, while tight seams between pieces should be maintained to prevent gaps that could impact performance.

By utilizing high mass density materials, such as crumb rubber and cork, acoustic underlays offer efficient energy use through noise control, reducing the impact of sound on occupants in adjacent rooms or units. Including acoustic underlays in renovation projects also helps ensure compliance with building insulation standards and soundproofing regulations, providing peace of mind for homeowners and builders.

Acoustic underlays installed beneath wood or laminate flooring can significantly reduce noise levels in rooms. By utilizing high-density materials like crumb rubber and cork, acoustic underlays offer efficient noise control, reducing the impact of noise on people in adjacent rooms or units.

Many acoustic underlays are made from environmentally friendly materials, such as recycled crumb rubber, cork, and natural wool. These sustainable materials reduce the need for virgin resources and help lower overall pollution. Additionally, some products are LEED certified, supporting sustainable building practices.

Common materials used in acoustic underlays include cork, foam, natural rubber, and recycled crumb rubber. Each material offers unique properties for noise reduction and thermal insulation, allowing users to select the best option for their specific needs.

Yes, certain acoustic underlays are designed to be used with underfloor heating systems. These underlays have low thermal resistance, allowing efficient heat transfer while also providing noise reduction. It is important to choose the right type of underlay for compatibility with underfloor heating.